T

Tbird64

Click here to upgrade

- Last seen

- Joined

- May 31, 2018

- Thunderbird Year

- 1964

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

Please

sign in or

join the Thunderbird

club free to access the search page and many other free site features.

If you forgot your password

click here

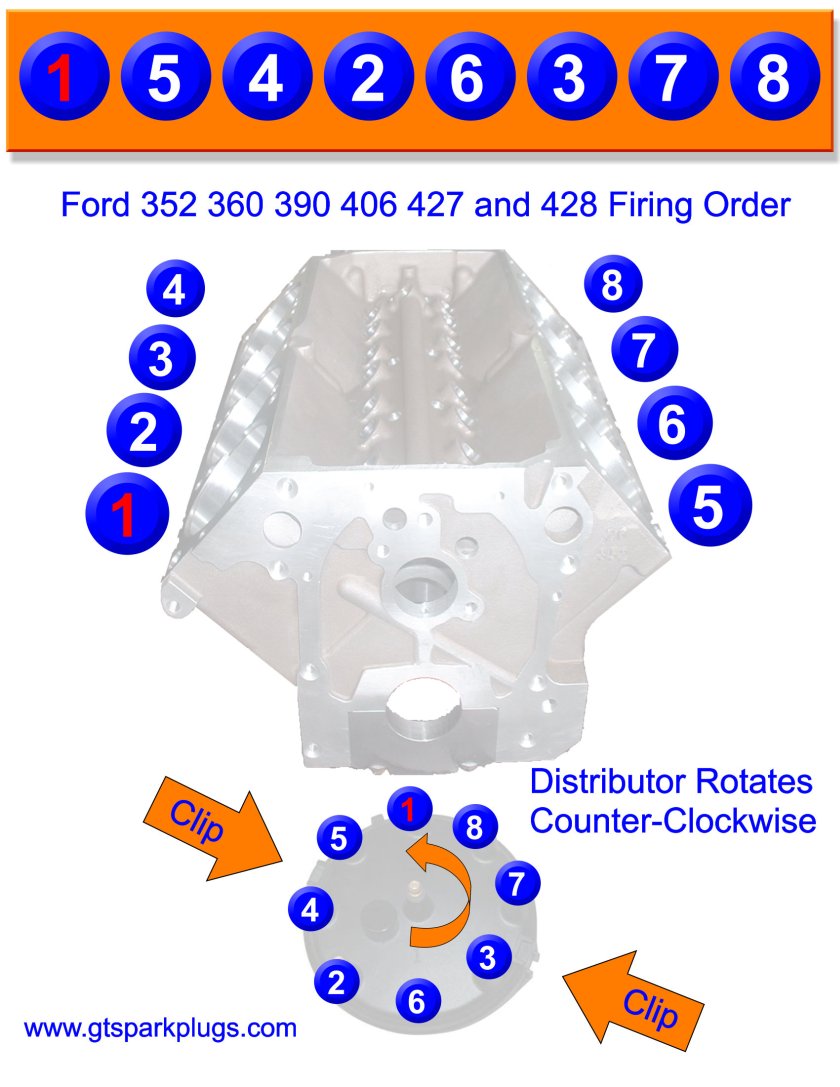

This I completely agree with! Do not rotate the engine with the distributor out or you will have to turn the engine by hand or bump it with the starter until it lines up again with #1 cylinder. Also the oil pump pick up shaft will almost never line up with the Distributor after you remove it. You will have to take something and rotate the oil pump pickup shaft then try and align with with the distributor as you get it to slot back in with the teeth on the cam gear. If you have to remove the distributor be very careful as the oil pump pick up will sometime get stuck in the hex slot in the distributor and come out with it.When you took it out did you mark where the rotor was pointing or line it up to #1 before removing it? It needs to go back in the same place. At the bottom of the distributor there is either a female hex or a slot. It is where the oil pump shaft slides in. That hex / slot needs to be lined up as you drop the distributor in. Did you rotate the engine at all after the distributor was out? Hopefully you didn't! If you moved the engine you will have to line it up to #1 cylinder and look down in the hole to see the orientation of the oil pump shaft and get it so that it will slip into the drive slot/hex at the bottom of the distributor as you lower it down into position. You also need to start with the rotor a little out of location (about one plug location) so that as you slide it down in you can twist the rotor to get it all the way down and engaged properly into the helical gear on the distributor shaft.

An absolute must. No other way or you could cause damage to your engine. However finding TDC on cylinder one is pretty easy.Unfortunately I did rotate the engine. Do you have to make sure cylinder one is a TDC?

OAO, Just curious? how do you think it could damage the engine?An absolute must. No other way or you could cause damage to your engine. However finding TDC on cylinder one is pretty easy..

Well wouldn’t too much either way be really hard on the engine? Like the starter or connecting rods? Too much advance really makes the engine work against itself right? I am not trying to sound like an expert here. Just mirroring things I have read about. Though I will say from experience that too much advance is VERY hard on your starter when trying to get the engine to turn over. That I have experienced myself.OAO, Just curious? how do you think it could damage the engine?

Well yes if you left it improperly set up it would over the long term probably wear things out faster than it should. But for purposes of popping in a distributor and getting it started then absolutely set everything where it belongs should not cause any damage to the engine.Well wouldn’t too much either way be really hard on the engine? Like the starter or connecting rods? Too much advance really makes the engine work against itself right? I am not trying to sound like an expert here. Just mirroring things I have read about. Though I will say from experience that too much advance is VERY hard on your starter when trying to get the engine to turn over. That I have experienced myself.